E-waste & circular economy: zero tech waste

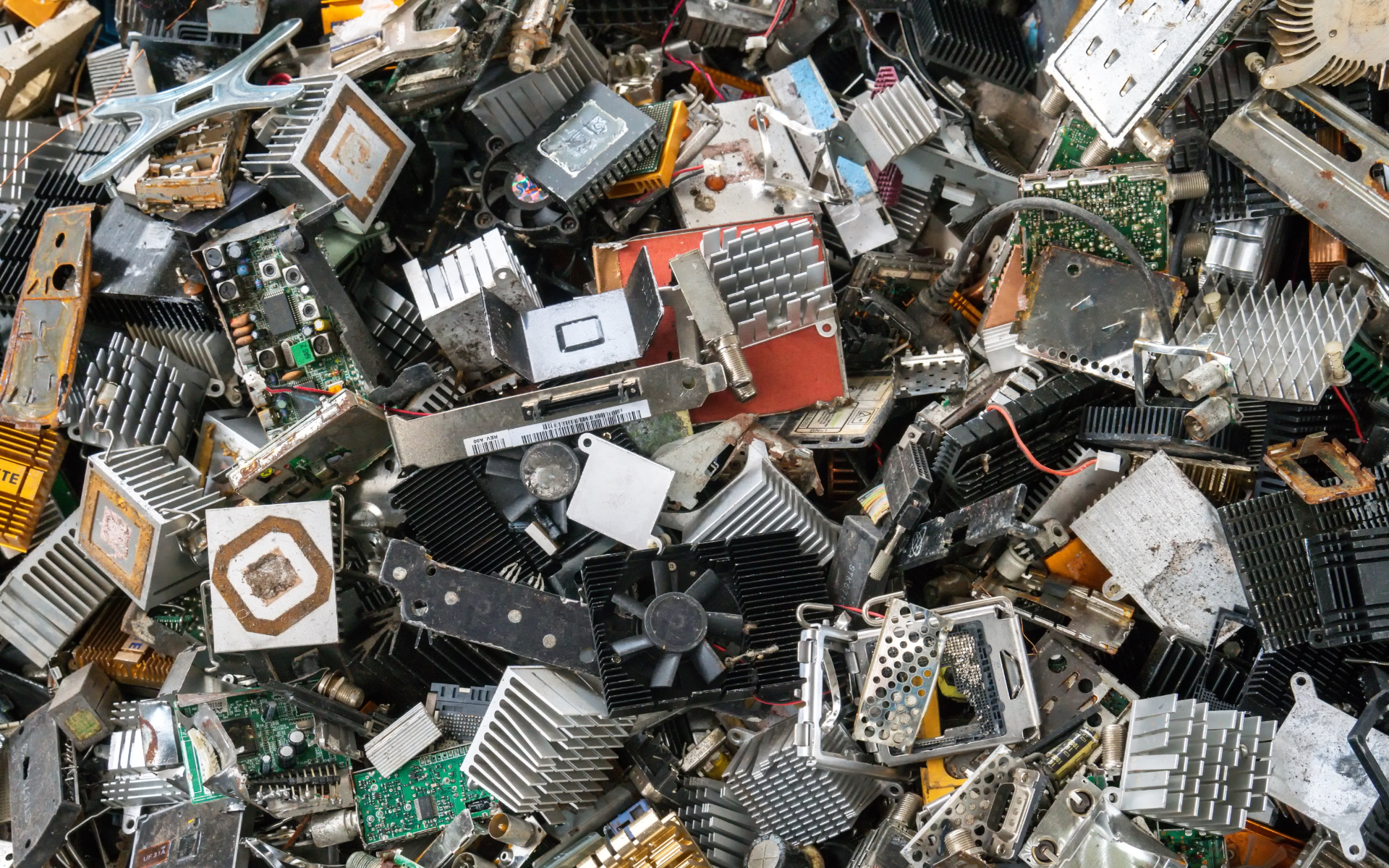

The technological acceleration of the past twenty years has transformed the way we produce, store, and consume data, but it has also left behind a growing trail of obsolete equipment. E-waste, or electronic waste, is now the fastest-growing waste category in the world, driven by increasingly shorter life cycles and a linear consumption model that is unlikely to remain sustainable. Companies, as major producers and consumers of hardware, find themselves at the center of a problem that can no longer be ignored.

At the same time, the circular economy paradigm offers an alternative scenario that turns waste into a resource and redesigns the entire technological life cycle. Becoming a “zero tech waste company” is no longer a theoretical exercise but a competitive strategy that helps optimize costs, reduce regulatory risks, enhance existing assets, and contribute meaningfully to sustainability. The core challenge lies in processes: rethinking the use of technology means intervening from design to disposal, through maintenance, refurbishment, and materials management.

From a linear model to a circular model

The traditional linear model — production, use, disposal — has revealed its limitations in a sector where miniaturization and high material density turn every device into a potential urban mine. Transitioning to a circular model means restructuring the hardware life cycle so that every component remains in the system for as long as possible. This involves the ability to extend the operational life of devices, recover rare materials, and drastically reduce the disposal of highly polluting electronic components.

The transition requires an accurate analysis of technological assets: companies must know the age, remaining performance, and repairability of each device. A centralized view of the hardware fleet makes it possible to anticipate replacements, schedule maintenance, and decide in time whether a device can be refurbished or reintegrated into secondary circuits. This data-driven approach replaces the logic of premature obsolescence with planning based on real business needs.

Technical management of the device life cycle

Reducing corporate e-waste is not just about the disposal phase; it begins as early as procurement. Choosing modular, easily repairable devices supported by extended firmware update programs can significantly reduce turnover. The most advanced companies include sustainability criteria in their purchasing processes, such as the availability of spare parts, warranty duration, and certification of material origin.

During the operational phase, predictive maintenance plays a key role. Through hardware monitoring tools, it is possible to detect degrading components in advance, reducing the risk of failures and enabling targeted interventions. Added to this is the option to virtualize certain functions, decreasing dependence on physical machines and extending the overall infrastructure life cycle.

Refurbishment and reintroduction into production cycles

When a device reaches the end of its primary use, the path toward disposal is not immediate. Refurbishment is an effective technical solution to recover value from hardware that would otherwise be discarded. Through testing, replacement of critical components, and installation of secure operating systems, laptops, servers, and smartphones can be restored to working condition and assigned to secondary uses.

Companies may choose to reintegrate these devices into departments with less demanding performance requirements or include them in certified donation or resale programs. This not only reduces overall IT infrastructure costs but also generates a positive social impact and contributes to closing the loop of the technological life cycle.

Material recovery and circular industrial supply chains

When refurbishment is no longer possible, material recovery comes into play. Electronic devices contain precious metals such as gold, palladium, and platinum, as well as rare earths essential for future technological production. Proper separation of components, extraction of critical materials, and reintegration into industrial processes reduce the need for new mining operations, lowering environmental impact and supply chain costs.

Companies that adopt reverse logistics strategies and collaborate with specialized facilities create a continuous flow of recycled materials that can be reintroduced into production. This reduces dependence on foreign suppliers and makes the technological supply chain more resilient in the face of geopolitical shocks or sudden shortages of raw materials.

Data security and digital responsibility

In the context of corporate e-waste, a crucial aspect is secure data management. Every discarded device may contain sensitive information, and its protection is an integral part of corporate digital responsibility. Before refurbishment or recycling, certified data wiping procedures must be used, following international standards such as NIST 800-88 or ISO/IEC 27040.

In the most critical cases, physical destruction of storage media is adopted to eliminate any remaining risk. This step provides assurance for both corporate security and regulatory compliance, especially in sectors handling highly sensitive data.

Toward a truly “zero tech waste” corporate culture

Achieving a “zero tech waste” objective requires a mindset shift involving every department. Employee training on conscious use of digital resources, adoption of internal policies to extend device life cycles, and collaboration with certified partners create an ecosystem where technology is no longer a consumable but a valuable asset.

Companies that embrace the circular economy do more than reduce environmental impact. They become more efficient, competitive, and capable of anticipating increasingly stringent regulations on electronic waste management. The result is a business model that integrates sustainability, innovation, and responsibility, paving the way for a future in which e-waste is no longer a problem but an opportunity.